Radiation and Industrial Polymers Types of Reactions Involved

Fluoropolymer (PTFE) Hose Industrial Applications

In the case of a PTFE hose, static electricity is caused when a nonconducting fluid flows at a high velocity through the PTFE natural core tube. When a static charge builds up in the tube of a PTFE hose, it will look for the path of least resistance to ground. If the tube is nonconductive,then the path of least resistance may be to pierce through the wall of the PTFE tube to the conductive Stainless Steel Braid and eventually to the metal fittings and back-to ground through the equipment to which the hose assembly is connected.

The purpose of a static dissipating tube on the inside of the hose is to provide an acceptable path of least resistance and allow the static build-up to dissipate through the core tube to the metal fittings and eventually to ground.

FLUOROPOLYMER HOSE CONSTRUCTION

Contains Media

Materials: Natural or Static-Dissipative PTFE with a Smoothbore or Convoluted Core

2. Reinforcement

Provides Resistance to Internal Pressure

Materials: Stainless Steel

FLUOROPOLYMER HOSE FEATURES

- Excellent chemical compatibility

- Handles extreme temperatures to +450°F

- Environmentally safe

- Low moisture permeability

- Low friction minimizes pressure drops and deposits

FLUOROPOLYMER HOSE APPLICATIONS/MARKETS

- Chemical transfer lines

- General hydraulics

- Compressed air/gases

- Adhesive dispensing

- Coolant Lines

- Medical Gases

IMAGES FOR FLUOROPOLYMER HOSE

Extrusion Foaming of PTFE Fluorocarbon Resins

INTRODUCTION

APPLICATIONS FOR MELT PROCESSABLE PERFLUORINATED RESINS

STRUCTURE AND PROPERTIES OF FLUOROPOLYMERS

GENERAL ASPECTS OF FOAMED INSULATION

EQUIPMENT REQUIREMENTS FOR FOAMING

Proper sizing of the extruder and appropriate screw design are key factors in the foaming process.

SAFETY CONSIDERATIONS

Types of extrusion

TYPES OF EXTRUSION:

Direct extrusion

Extrusion is a compressive deformation process in which a block of metal is squeezed through an orifice or die opening in order to obtain a reduction in diameter and increase in length of the metal block. The resultant product will have the desired cross-section. Extrusion involves forming of axisymmetric parts. Dies of circular on non-circular cross-section are used for extrusion. Generally, extrusion involves greater forming forces. Large hydrostatic stress in extrusion helps in the process by enhancing the ductility of the material. Metals like aluminium, which are easily workable, can be extruded at room temperature. Other difficult to work metals are usually hot extruded or warm extruded. Both circular and non circular parts can be obtained by extrusion. Channels, angles, rods, window frames, door frames, tubes, aluminium fins are some of the extruded parts.

Direct extrusion:

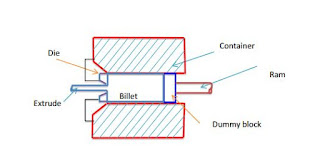

Direct extrusion, also called forward extrusion, is a process in which is the billet moves along the same direction as the ram and punch do. Sliding of billet is against stationary container wall.Friction between the container and billet is high. As a result, greater forces are required. A dummy block of slightly lower diameter than the billet diameter is used in order to prevent oxidation of the billet in hot extrusion. Hollow sections like tubes can be extruded by direct method, by using hollow billet and a mandrel attached to the dummy block.

Extrusion force, which is the force required for extrusion, in direct extrusion, varies with ram travel as shown in figure above. Initially the billet gets compressed to the size of container, before getting extruded. Also, initially static friction exists between billet and container. As a result the extrusion pressure or force increases steeply as shown. Once the billet starts getting extruded, it length inside the container is reduced. Friction between billet and container now starts reducing. Therefore, extrusion pressure reduces. The highest pressure at which extrusion starts is called breakthrough pressure. At the end of the extrusion, the small amount of material left in the container gets pulled into the die, making the billet hollow at centre. This is called pipe. Beyond pipe formation, the extrusion pressure rapidly increases, as the small size billet present offers higher resistance. As the length of the billet is increased, the corresponding extrusion pressure is also higher because of friction between container and billet. Therefore, billet lengths beyond 5 times the diameter are not preferred in direct extrusion.

Direct extrusion can be employed for extruding solid circular or non-circular sections, hollow sections such as tubes or cups.

The intricate process of plastic extrusion and what it makes

plastic extrusion and custom molding

Plastic extrusion has become quite a popular activity in industries and even technical schools are offering courses to enable individuals to get into this career. One of the fastest growing careers in the world is plastic and rubber mould designing. Custom molding is one activity that all brands seem to desire. They want plastic bottles for their sodas in this form or the other. Brands want to sell the most stylish yet functional water bottles. There are others that want to set up the finest quality plastic and rubber pipes for industrial and even residential purposes. These are just some of the reasons why the career is continually growing in popularity.

What is extrusion?

So people are talking about this process over and ever but in all honesty very few know exactly what it is. Well, generally plastic extrusion is a process whereby plastic melted down and turned into a continuous form. This process is mainly used n the production of items such as pipes, tubing, wire insulation, railing, fencing and so much more. In other words the applicability of extrusion is so high and hence its popularity all over the world. At the most basic level the process involves heating and molding to produce a particular shape.

The process involves use of plastic resin. These are small plastic beads that are fed into the heated barrel of the extruder. The resin is pushed through the barrel by a rotating screw where a temperature of between 392 and 527 degrees Fahrenheit melts the resin. This temperature depends mainly on the polymer that has been used in the creation of the resin. In order to reduce the likelihood of overheating the resin, the heat is increased gradually from one side of the barrel towards the other one.

There is a screen at the front of the barrel which is used to filter out contaminants that might be present in the molten resin. Once the resin has passed through the screen it is sent through a die of particular shape. This gives the product its profile. The profile can be made continuously at whatever length the manufacturer fancies. The final stage is usually the cooling. This is done by use of a water bath. Normally plastic holds heat quite well and therefore cooling can take quite some time to complete. The water bath is usually sealed there is a vacuum that is employed to prevent the product from losing the shape as it cools.

Common types of extrusion

There are various types of plastic extrusion which produce various products. They include:

1. Blow film extrusion

This one is used in the making of things such as plastic shopping bags. The die in this case is normally an upright cylinder where the melted resin is poured.

2. Sheet extrusion

It is also called film extrusion and it is mainly employed in the making of plastic films and sheets. Instead of cooling by water bath, the sheets are cooled by being pulled through a series of about three pinch rollers. The rollers also determine the thickness of the final product in question.

3. Tubing extrusion

This method makes products like medical tubing and straws. The process is rather similar to the basic extrusion but at the die stage a pin is placed inside the die. The melted resin is then pushed into the die and it forms around the pin known as a mandrel.