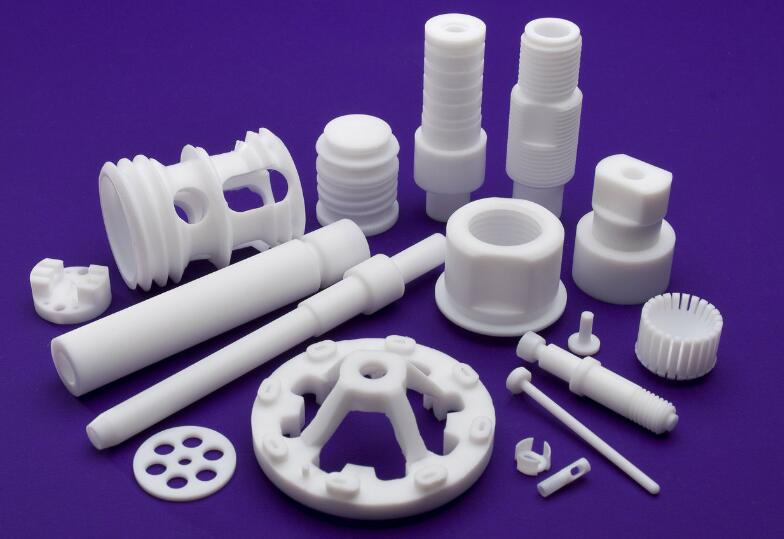

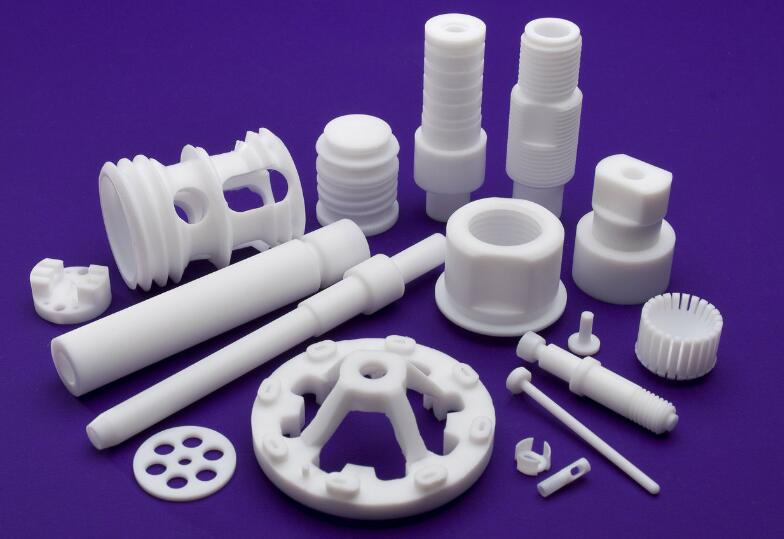

7 fillers to enhance the performance of virgin PTFE sealing

PTFE (Polytetrafluoroethylene) has become a commonly used material in sealing applications where other materials do not meet temperature, chemical compatibility, friction, or wear requirements. Many users are unaware that “fillers” may be added to PTFE in order to enhance certain characteristics not found in virgin PTFE. Virgin PTFE possesses “creep” behavior that may reduce effectiveness in mechanical applications.

Significant deformation of virgin PTFE may occur over time even at room temperatures. The use of fillers improves the physical attributes of virgin PTFE, including creep and wear resistance. Which filler to use certainly depends on the application. Some of the common fillers include:

1,Glass is the most common filler for PTFE. Widely used in hydraulic piston rings, glass gives good wear resistance, low creep, and good compressive strength. Glass also has excellent chemical compatibility. The percentage of glass varies between 5 percent and 40 percent. The major disadvantage is that glass-filled PTFE compounds are abrasive to mating surfaces, especially in rotary applications.

2,Molybdenum disulfide (MoS2) improves wear resistance and further lowers the coefficient of friction. “Moly” is typically combined with other fillers (such as glass and bronze).

3,Carbon imparts excellent compression (low deformation under load) and wear resistance, good thermal conductivity, and low permeability. Carbon-filled PTFE compounds are not as abrasive as glass-filled compounds, but they are still more abrasive than polymer-filled compounds. The percentage of carbon added varies between 5 percent and 15 percent. Carbon-filled compounds have excellent wear and friction properties when combined with graphite. Carbon fiber lends better creep resistance than carbon powder, but fiber is more expensive.

4,Graphite is a crystal modification of high-purity carbon. Its flaky structure imparts excellent lubricity and decreased wear. Percentages of this filler vary between 5 percent and 15 percent. Graphite is often combined with other fillers (especially carbon and glass).

5,Bronze lends excellent wear resistance and thermal conductivity. Bronze-filled materials have higher friction than other filled PTFE compounds, but that can be improved by adding moly or graphite. Bearing and piston ring applications often use compounds containing 55 percent bronze – 5 percent moly. Bronze-filled compounds have poorer chemical resistance than other PTFE compounds. Bronze, when used as a filler, is added in percentages of weight between 40 percent and 60 percent.

6,Ekonol is thermally stable aromatic polyester. When blended with PTFE, it produces a composite material with excellent high temperature and wear resistance. Ekonol will not wear mating metal surfaces, making it good for rotary applications. Ekonol-filled materials are also good for food service.

7,Polyimide is another type of polymeric filler, which offers superior wear and abrasion resistance. Polyimide-filled PTFE compounds have about the lowest friction properties of all filled PTFE materials, so they provide great performance in non-lubricated (dry) applications. They will not abrade mating surfaces (even soft materials such as brass, stainless steel, aluminum, and plastic). Polyimide is one of the most expensive PTFE fillers, however.