Methods for Welding

EXTRUSION WELDING

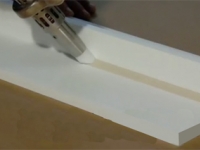

Extrusion welding allows the application of bigger welds in a single weld pass. It is the preferred technique for joining material over 6 mm thick. Welding rod is drawn into a miniature hand held plastic extruder, plasticized, and forced out of the extruder against the parts being joined, which are softened with a jet of hot air to allow bonding to take place.

Extrusion welding allows the application of bigger welds in a single weld pass. It is the preferred technique for joining material over 6 mm thick. Welding rod is drawn into a miniature hand held plastic extruder, plasticized, and forced out of the extruder against the parts being joined, which are softened with a jet of hot air to allow bonding to take place.HOT GAS WELDING

Hot gas welding, also known as hot air welding, is a plastic welding technique which is analogous to metals, though the specific techniques are different. A specially designed heat gun, called a hot air welder, produces a jet of hot air that softens both the parts to be joined and a plastic filler rod, all of which must be of the same or a very similar plastic. Hot air/gas welding is a common fabrication technique for manufacturing smaller items such as chemical tanks, water tanks, heat exchange and plumbing fitting. Two sheets of plastic are heated via a hot gas or a heating element and then rolled together. This is a quick welding process and can be performed continuously.

Hot gas welding, also known as hot air welding, is a plastic welding technique which is analogous to metals, though the specific techniques are different. A specially designed heat gun, called a hot air welder, produces a jet of hot air that softens both the parts to be joined and a plastic filler rod, all of which must be of the same or a very similar plastic. Hot air/gas welding is a common fabrication technique for manufacturing smaller items such as chemical tanks, water tanks, heat exchange and plumbing fitting. Two sheets of plastic are heated via a hot gas or a heating element and then rolled together. This is a quick welding process and can be performed continuously.SPEED TIP WELDING

With speed welding, the plastic welder, similar to a soldering iron in appearance and wattage, is fitted with a feed tube for the plastic weld rod. The speed tip heats the rod and the substrate, while at the same time it presses the molten weld rod into position. A bead of softened plastic is laid into the joint, and the parts and weld rod fuse. With some types of plastic such as polypropylene, the melted welding rod must be “mixed” with the semi-melted base material being fabricated or repaired. These welding techniques have been perfected over time and have been utilized for over 50 years by professional plastic fabricators and repairers internationally. Speed tip welding method is a much faster welding technique and with practice can be used in tight corners. A version of the speed tip “gun” is essentially a soldering iron with a broad, flat tip that can be used to melt the weld joint and filler material to create a bond.

With speed welding, the plastic welder, similar to a soldering iron in appearance and wattage, is fitted with a feed tube for the plastic weld rod. The speed tip heats the rod and the substrate, while at the same time it presses the molten weld rod into position. A bead of softened plastic is laid into the joint, and the parts and weld rod fuse. With some types of plastic such as polypropylene, the melted welding rod must be “mixed” with the semi-melted base material being fabricated or repaired. These welding techniques have been perfected over time and have been utilized for over 50 years by professional plastic fabricators and repairers internationally. Speed tip welding method is a much faster welding technique and with practice can be used in tight corners. A version of the speed tip “gun” is essentially a soldering iron with a broad, flat tip that can be used to melt the weld joint and filler material to create a bond.PLASTIC WELDED APPLICATIONS INCLUDE:

- Thermoplastic tanks for plating, anodizing, cleaning, wastewater treatment and chemical processing industries

- Rotationally Molded Tanks

- Flexible Drop-in Liners

- Sinks

- Sematech approved wet benches

- One piece construction of cabinets, wet benches, wafer stackers, polishers, spin dryers, and tanks

- Fume hoods

- Ducts and fittings for exhaust and ventilation

Partial listing of materials for plastic welding:

- PVC, CPVC, HDPE,PP, PVDF, LDPE, HDPE.

- Corzan® FMRC 4910 Listed 3002299.

- Kytec® (MP-20 resin) Listed 3D1Q5.AM.

- FR-CP7-D Listed 3D7 Q7.AM.

- Halar® 901(Ultra pure for DI & UPW systems).

- Clear Halar® (453) Listed 4D7Q9.AM.

- Corzan® 11 Listed 3010025.

- Opaque Halar®.

- FM4910 approved materials specified for use in the semiconductor and clean room industries