Plastic Extrusion

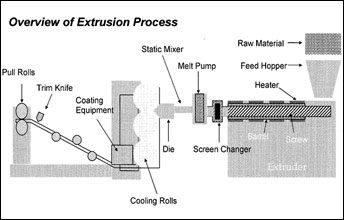

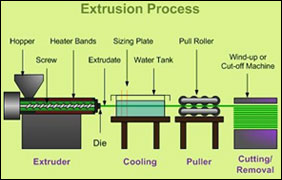

Plastic extrusion is defined as a manufacturing process (high-volume), in which the raw plastic / raw plastic material is melted and then formed in a continuous profile. With this process various products can be manufactured such as pipe/tubing, window frames, weather stripping, wire insulation, and adhesive tape. In general, the plastic materials that are used in the process of extrusion are Polyethylene, Polypropylene, Nylon (Polyamides), Polystyrene, Polycarbonate, Acetal, Acrylic, and Acrylonitrile Butadiene Styrene (ABS). These are just the primary plastic materials that are extruded. Apart from these, there are many other plastic materials that can be / are extruded all around. Plastic extrusion is defined as a manufacturing process (high-volume), in which the raw plastic / raw plastic material is melted and then formed in a continuous profile. With this process various products can be manufactured such as pipe/tubing, window frames, weather stripping, wire insulation, and adhesive tape. In general, the plastic materials that are used in the process of extrusion are Polyethylene, Polypropylene, Nylon (Polyamides), Polystyrene, Polycarbonate, Acetal, Acrylic, and Acrylonitrile Butadiene Styrene (ABS). These are just the primary plastic materials that are extruded. Apart from these, there are many other plastic materials that can be / are extruded all around.Plastic Extrusion Process In the processing of plastic raw materials through the extrusion process, the raw thermoplastic material is gravity fed from a hopper (top mounted) into the barrel, which is a part of extruder. The raw material is in the form of small beads and is generally called resin, in industrial terms. Before the material arrives at the hopper, it can be (& often is) mixed with various additives like colorants & UV inhibitors (in pellet or liquid form). The further steps of the process of plastic extrusions are as follows: Through the feed throat, the material enters and comes in contact with screw. The feed throat is an opening near the rear side of barrel. The rotating screw, which is generally turning at 120 rpm (max.) forces the plastic beads ahead in the barrel. At this time, the barrel is heated to the required melt temperature of the molten plastic. This temperature can be within the range of 200 °C (392 °F) to 275 °C (527 °F), which depends on the polymer being extruded. In most of the plastic extrusion processes, a specific heating profile is set for the barrel. Inside the barrel, three or more individual / separated PID controlled heater zones slowly enhance the barrels' temperature from the rear side (from where the entry of plastic takes place) to the front side. This permits the plastic beads to slowly melt as these are forced through the barrel, lowering the risk of overheating that may result in polymer's degradation. Additional heat is contributed from the intense friction and pressure that takes place in the barrel. Actually, if a specific extrusion line is operating on a fast-enough material, the heaters can be switched off & the melt temperature can be maintained by the effect of friction and pressure alone in the barrel. In a large number of extruders, there are cooling fans for keeping the temperature less than a set value, in case there is too much heat generation. In case the forced air cooling seems to be incommensurate, then cast-in heater jackets are used. These commonly use a closed loop of distilled water during the exchange of heat with the city water or tower. Further steps of plastic extrusions are as follows:  In the barrels' front, molten plastic leaves the screw & moves through a screen pack for the removal of contaminants present in the melt. Then, a breaker plate is used to reinforce the screens as at this point the pressure may exceed 5000 psi (34 Mpa). Breaker plate is a thick metal puck that has many holes drilled in it. The assembly of screen pack / breaker plate also serves the purpose of creating a back pressure inside the barrel, which is needed for proper mixing and uniform melting of the polymer. The amount of generated pressure can be easily 'tweaked' by changing the screen pack composition i.e., number of screens, wire weave size of the screens, & various other parameters. The combination of breaker plate & screen pack also serves the purpose of converting the "rotational memory" of molten plastic into the "longitudinal memory". After the molten plastic passes through the breaker plate, it enters the die. The die provides a specific profile to the final product and it must be designed in such a way that the flow of molten plastic is uniform from a cylindrical profile to the product's profile shape. Until, it is a continuous profile any imaginable shape can be developed. At this stage, the product is now cooled by pulling the extrudate by way of water bath. It is well known fact that plastics are extremely good thermal insulators & hence are difficult to cool swiftly. In a pipe or tube extrusion line, a carefully controlled vacuum is used to act on the sealed water bath. This is done for avoiding the collapse of newly formed and still molten pipe or tube. For products like plastic sheeting, the required cooling is acquired by pulling through a definite set of cooling rolls. |