Profile Extrusion - Plastic Extrusion

Profile extrusion is a process by which various plastic materials are used to develop quality plastic products. These products have a continuous cross-section such as pipe, drinking straws, decorative molding, eavestroughing, window trimming and many others. The basic procedure of profile extrusion is that the polymer is melted into a hollow mold cavity, under the influence of high pressure.

Process of Profile Extrusion

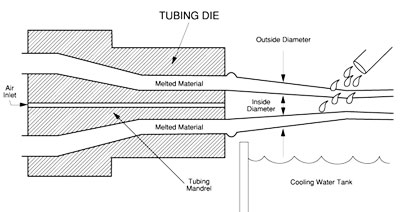

A wide range of special profile extrusion equipment are used to carry out this process effectively. In this process, first the plastic (pellet form) is fed into the machine hopper / extruder. Along with this, the material is constantly conveyed in the forward direction by the way of rotating screw which is placed inside the heated barrel that is being regularly softened by friction as well as heat.

Then, the softened plastic is thrown out via a die, straight in the cool water that solidifies the product. From this point, it is conveyed to take-off rollers that actually pull the softened plastic from the die. The die is basically a metal plate which is placed at the extruders' end with a section that is cut out of its interior. This cutout along with the speed of take-off rollers are the two major factors that determine the final cross-section of manufactured product.

Typical Raw Materials For Plastic Profiles

Typical Raw Materials For Plastic Profiles

- HDPE (High Density Polyethylene)

- LDPE (Low Density Polyethylene)

- LLDPE (Linear Low Density Polyethylene)

- PETG

- Flexible PVC

- Butyrate

- Polypropylene

- Polystyrene

- ABS

Advantages And Disadvantages of Profile Extrusion

The only main disadvantage of the profile extrusion is the limitations in the design possibilities, which is due to the linear nature of the process. It has various advantages as well that are as follows:

- Equipment widely available in all geographical areas

- Relatively low tooling costs

- Inexpensive process

- Product combinations possible

- Design freedom

Typical Applications & Design Possibilities

There are number of applications where the process of profile extrusion is extremely useful. Also, there are many design possibilities with the use of this process. Typical applications and design possibilities of the profile extrusion process are as follows:

- Windows profile

- Sealing sections

- Modular drawer profiles

- Decorative trim