Sheet / Film Extrusion - Plastic Extrusion

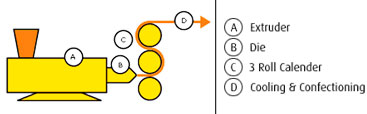

| Sheet / Film Extrusion is the process which is used for the products like plastic sheets or films. During the extrusion of these plastic materials, the required cooling is achieved by the action of pulling which is done through a specific set of cooling rolls that are generally three or four in number. These cooling rolls are also called calender or “chill” rolls. Extremely fast running speed develops “nerve”, which is an undesirable condition. This condition occurs when insufficient contact time is permitted to dissipate the heat, which is available in the extruded plastic. In the plastic sheet extrusion, the rolls deliver the required cooling in addition to determining the sheet thickness along with surface texture. This is done specially in the case of structured rolls; i.e. levant, smooth, haircell, etc). Commonly, co-extrusion is used for applying one or more layers for acquiring various specific properties like soft touch or "grip", UV-absorption, matte surface or energy reflection. The units for the solid sheet extrusion comprises minimum one Extruder along with one sheet extrusion die. These are supported by polishing stack which commonly includes 3 calenders that calibrate & cool the sheet with the use of their calender nips or surfaces. Behind this, the draw-off rolls to cool air and roller conveyor are located. Then, finally the sheet is cut and stored.  Sheet Extrusion Characteristics Sheet Extrusion Characteristics

Thermoforming is a general extrusion process (more of a post-extrusion process) for the stock of plastic sheets / films. In this process, the plastic sheet is heated till a soft plastic is formed by the way of a mold in a new shape. In case of use of vacuum, this process if generally called Vacuum Forming. In the process of thermoforming, orientation is immensely important and largely affects the forming cycle times. Orientation is defined as the ability or available density of the sheet that is to be drawn into the mold. This sheet can have the depth range of 1 to 36 inches in general. The process of thermoforming can range from the online bended pieces (e.g. displays) to various sophisticated shapes (e.g. computer housings) that normally seem to be injection molded mainly due to the the wide range of possibilities in thermoforming like undercuts, inserts, and divided molds. |