Material Comparison - PVC & PTFE

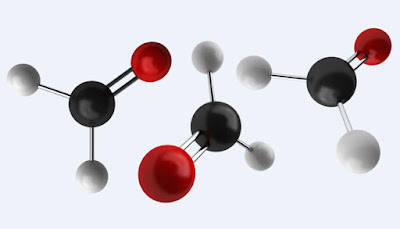

PTFE's significant chemical, temperature, moisture, and electrical resistances make it an ideal material whenever products, tools, and components need to be durable and reliable in even the most strenuous applications. On top of this, PTFE coated wire boasts unique low-temperature durability and fire resistance that make it a good choice for a constantly growing list of products, components, and applications.

PVC cables are manufactured at a much lower cost because they don’t have to meet the high temperature rating that PTFE cables do. PVC stands for Polyvinyl Chloride which is a compound engineered to be used in electronics and other indoor applications.

PVC electronic cables meet a 105°C temperature rating in 300 or 600 volts. They’re manufactured with flexible copper strands and PVC insulation on the inner conductors. They sometimes come with an aluminum overall foil shield and a tinned copper drain wire.

Now that you know the construction of a PVC cable you’ll probably understand why a PTFE cable is much more expensive. PTFE compound is used to manufacture a 200°C temperature material to cover the copper conductors. The engineering involved in creating a 200°C cable is much more involved than the process of creating a 105°C cable.

| Property Name | Units | ABS/PVC Alloy | PTFE Filled |

|---|---|---|---|

| Specific Heat Capacity | BTU/lb-°F | 0.382 | |

| Shear Modulus | ksi | ||

| Compressive Yield Strength | psi | 3050 | 5710 |

| Poisson's Ratio | |||

| Dielectric Constant | 3.3 | 3.7 | |

| Dielectric Strength | kV/in | 508 | 467 |

| Elongation at Break | % | 100 | 9.4 |

| Flexural Yield Strength | psi | 7030 | 9820 |

| Modulus of Elasticity | ksi | 319 | 348 |

| Hardness, Rockwell R | 88 | 110 | |

| Tensile Strength, Ultimate | psi | 4030 | 6580 |

| Tensile Strength, Yield | psi | 5420 | 8270 |

| Electrical Resistivity | ohm-cm | 1.00e+14 | 3.00e+15 |

| Density | lb/in³ | 0.0423 | 0.0531 |

| Max Service Temperature, Air | °F | 170 | 212 |

| Thermal Conductivity | BTU-in/hr-ft²-°F | 1.87 | 1.67 |

| Fracture Toughness | ksi-in½ |