Plastic Sheet - Polypropylene Sheet

Plastic sheeting (also known as plastic tarpaulin, tarp or polythene sheet) is a sheet of strong, fl exible, water resistant or waterproof material. Although different qualities exist, those suitable for humanitarian relief are made from polyethylene. A standard sheet has a black woven or braided core and is laminated on both sides. All plastic sheeting must reach minimum performance standards .

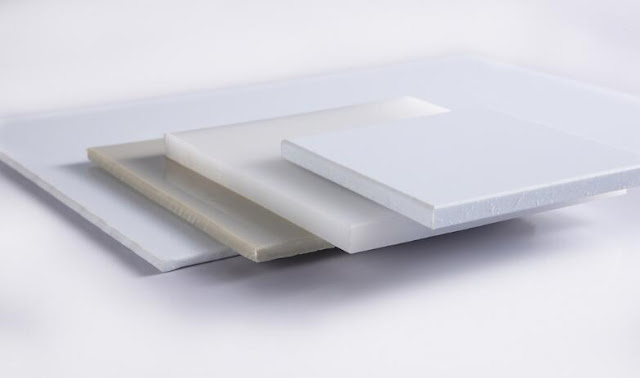

Polypropylene is a crystalline plastic that is known for high strength-to-weight ratio, excellent chemical resistance and high performance in thermoforming and corrosive environments. Polypropylene sheet is often used for orthotic and prosthetic devices, plating and anodizing process equipment, plenums, manifolds, and pump components.

Features of Polypropylene Sheet:

- Appropriate for applications to 180°F(82°C).

- Low moisture absorption.

- Resists most acids, alkalis and solvents.

- Corrosion resistant.

- Thermoforming performance.

- Meets USDA federally inspected meat and poultry packing guidelines.

PTFE Barbell

Food Grade Tubing

PTFE Forming and Fabrication - Working Speeds

CHOOSE CORRECT WORKING SPEEDS

Industrial Hoses - stainless steel braided hyperline PTFE Hose

Reinforcement:Single or double PTFE stainless steel braid

Working temp.:From -70°C up to +260°C (working pressure depends on temperature)

tables by 0.75% for each 1°C of temperature rise above +130°C.

Example: at +170°C temperature, maximum working pressure for hyperline PTFE hose is:

320 bar - (170°C - 130°C) x 0.75 = 320 bar - 30% = 224 bar.

Safety factor (working pressure/ bursting pressure) is 1:3.

PROPERTIES

Temperature Rating : The temperature rating is from -70° (-94°F) to +260°C (500°F), but the maximum working pressure (MWP) must be reduced by 1% for each 1°C above 130°C (1% for each 1.8°F above 266°F).

Fluoropolymer Monomer Properties

Skiving Tubing / Pipe